Looking for LEDsupplyplus.com?

LEDsupplyplus.com is now a part of HitLights!

Don't worry you're in the right place!

HitLights now owns the domain ledsupplyplus.com but does not own the business, its operations, or any associated liabilities. Any references to the previous business are for historical purposes only and do not indicate an ongoing relationship.

Looking for LEDsupplyplus.com?

LEDsupplyplus.com is now a part of HitLights!

Don't worry you're in the right place!

HitLights owns the domain ledsupplyplus.com but not the business, its operations, or liabilities. Any references to the former business are for historical context only.

Discover Hitlights

Discover Hitlights

Need to Know More?

check out some of our frequently asked questions below

What does it mean that HitLights owns the LEDsupplyplus.com domain?

This means that HitLights now controls the domain, but does not own the original business.

Will I still find the same products on LEDsupplyplus.com?

You can expect to find similar or improved LED products available at hitlights.com but may not be all.

Are my previous orders or accounts still valid?

No, previous orders and accounts from the old business are not transferred to HitLights.

Will there be any changes to customer service?

Customer service will be handled by HitLights, which operates independently from the previous business associated with this domain. Our team is dedicated to providing expert technical and customer support, ensuring a seamless experience for our customers.

What happens to the old business associated with LEDsupplyplus.com?

The old business is separate and no longer operates under that domain; any references are for historical context only.

Who is Hitlights?

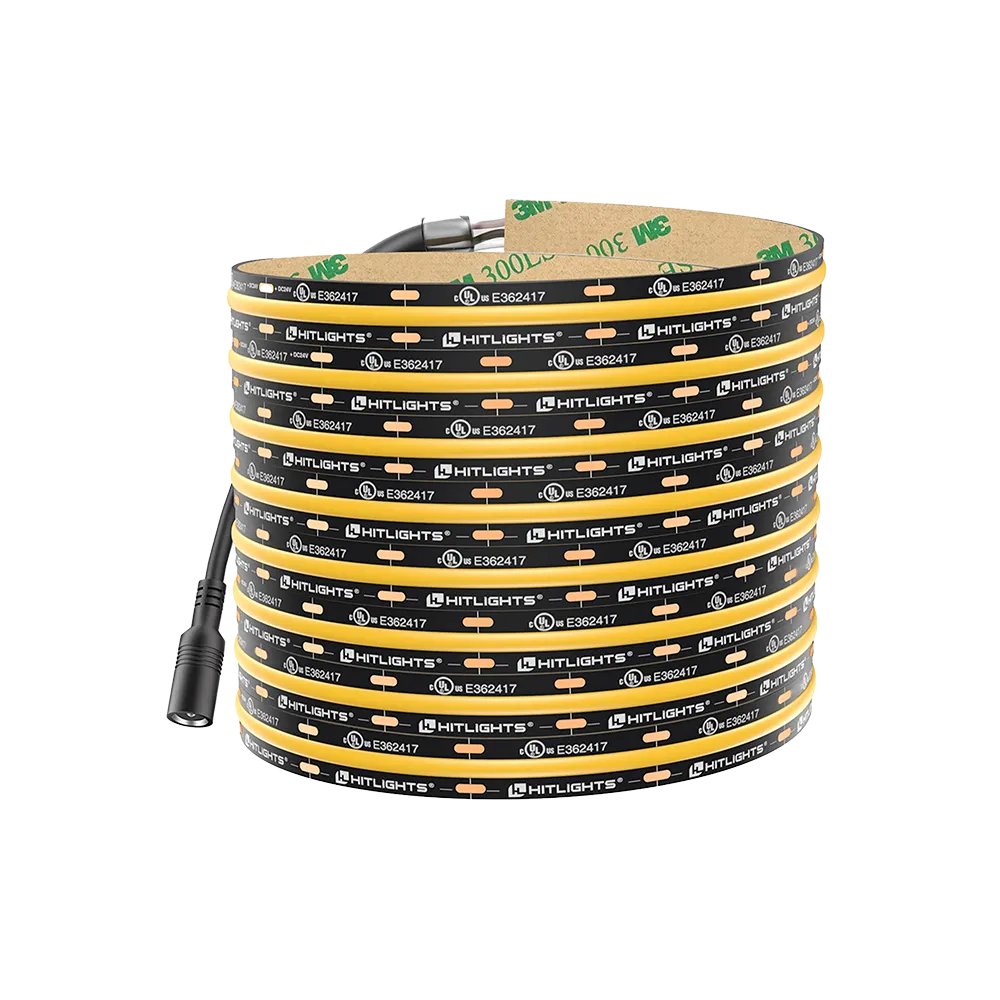

Since 2010, HitLights has been a trusted supplier of UL-Listed LED strip lights, power supplies, and accessories. We offer factory-direct products, expert support, and customizable solutions to make your lighting projects shine brighter and last longer.

Need to Know More?

check out some of our frequently asked questions below

What does it mean that HitLights owns the LEDsupplyplus.com domain?

This means that HitLights now controls the domain, but does not own the original business.

Will I still find the same products on LEDsupplyplus.com?

You can expect to find similar or improved LED products available at hitlights.com but may not be all.

Are my previous orders or accounts still valid?

No, previous orders and accounts from the old business are not transferred to HitLights.

Will there be any changes to customer service?

Customer service will be handled by HitLights, which operates independently from the previous business associated with this domain. Our team is dedicated to providing expert technical and customer support, ensuring a seamless experience for our customers.

What happens to the old business associated with LEDsupplyplus.com?

The old business is separate and no longer operates under that domain; any references are for historical context only.

Who is Hitlights?

Since 2010, HitLights has been a trusted supplier of UL-Listed LED strip lights, power supplies, and accessories. We offer factory-direct products, expert support, and customizable solutions to make your lighting projects shine brighter and last longer.